安装文件下载:

GE MBE IO Server Version 7.46.zip

(21.19 MB, 售价: 60 E币)

GE MBE IO Server Version 7.46.zip

(21.19 MB, 售价: 60 E币)

The MBE driver requires the following software:

Operating System

* Microsoft Windows Server 2016

* Microsoft Windows 10

* Microsoft Windows Server 2012

* Microsoft Windows 8 32 and 64-bit (WoW64)

* Microsoft Windows Server 2008 R2 64-bit (WoW64)

* Microsoft Windows 7 32 and 64-bit (WoW64)

* Microsoft Windows Server 2008 SP2

* Microsoft Windows Vista?Business or Ultimate Edition

* Microsoft Windows Server 2003, SP2 or greater

* Microsoft Windows XP Professional, Service Pack 2 or greater

* Internet Explorer 5.0 or greater.

* GEIP software or hardware license.

The following new features were added to thre MBE driver as part of this release:

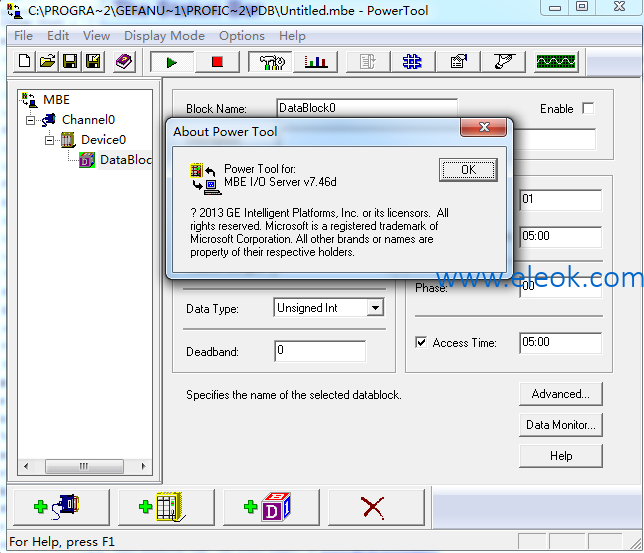

v7.46d

* Validated running under Windows Server 2016

* Corrected issue which occurs on newer Windows operating systems (Win7 and up).Occasionally after a reboot the card numbers configured for the Channels are found to be invalid. This occurs because the OS sometimes re-organizes the list of interfaces that was used to select the card number. To resolve this situtation, the MBE 7.46d has been modified. It now also saves the MAC address, and searches the list of interfaces for the MAC/IP pair when the configuration is loaded.When upgrading from a previous version of this driver, or opening a configuration file created with a previous version of this driver ... it is strongly recommended that the user follow the process below:

1) Using the PowerTool ... open each older version configuration file;

2) For each channel;

a) Change the Primary and Backup card numbers to a different card number.

b) Change the Primary and Backup card numbers to the index of the card

which displays the desired IP address.

3) Save the configuration file.

v7.46c

* MBE validated runing under Windows 10.

The MBE I/O version 7.x I/O driver provides the interface and communications protocol between Modbus Ethernet hardware and your process control software. Version 7.x drivers incorporate the following attributes to provide flexibility and ease-of-use:

OLE Automation technology

FIX integration

Event-driven architecture

OLE for Process Control compliance

OLE Automation Technology

Version 7.x drivers incorporate OLE Automation technology and expose their features to scripting tools and other applications. Because the drivers are OLE Automation applications, you can:

Create and manipulate objects exposed in the I/O Server from another application.

Create tools that access and manipulate driver objects. These tools can include embedded macro languages or external programming tools.

The I/O driver consists of the following OLE components:

The I/O Server – The core executable program. The I/O Server maintains the driver's channel, device, and datablock objects, performs all required functions for communicating with the process hardware, and exposes the methods and properties to other applications.

The I/O Driver Power Tool – A client application to the I/O Server with a graphical user interface. The Power Tool accesses the I/O Server and lets you view and modify channel, device, and datablock properties.

You can also view and modify driver properties with a custom client application developed specifically for your system. Refer to Creating Custom Client Applications to learn more about creating your own client application.

Integration with FIX

Version 7.x drivers let you automatically add addresses to the driver configuration while you are configuring your iFIX Database. When you add a block to the database that accesses a point in the hardware that you have not configured, the point is automatically added to the I/O Server and polled for data. Refer to Feature: Creating Datablocks Automatically in iFIX Database Manager to learn more about this feature.

Event-Driven Architecture

Version 7.x drivers are event-based rather than time-based, reducing CPU time and increasing performance.

OPC Compliance

Version 7.x drivers also comply with the OLE for Process Control (OPC) v1.0a standard. Any 1.0a OPC client application can access process hardware data through the I/O Server. Refer to Feature: Using the OLE for Process Control (OPC) Functionality to learn more about the advantages of OPC.

【必读】版权免责声明

1、本主题所有言论和内容纯属会员个人意见,与本论坛立场无关。2、本站对所发内容真实性、客观性、可用性不做任何保证也不负任何责任,网友之间仅出于学习目的进行交流。3、对提供的数字内容不拥有任何权利,其版权归原著者拥有。请勿将该数字内容进行商业交易、转载等行为,该内容只为学习所提供,使用后发生的一切问题与本站无关。 4、本网站不保证本站提供的下载资源的准确性、安全性和完整性;同时本网站也不承担用户因使用这些下载资源对自己和他人造成任何形式的损失或伤害。 5、本网站所有软件和资料均为网友推荐收集整理而来,仅供学习用途使用,请务必下载后两小时内删除,禁止商用。6、如有侵犯你版权的,请及时联系我们(电子邮箱1370723259@qq.com)指出,本站将立即改正。

|