支持操作系统:

Windows(R) 8.1 Pro (32bit,64bit)

Windows(R) 10 (32bit,64bit) Recommended Version 2004 or higher

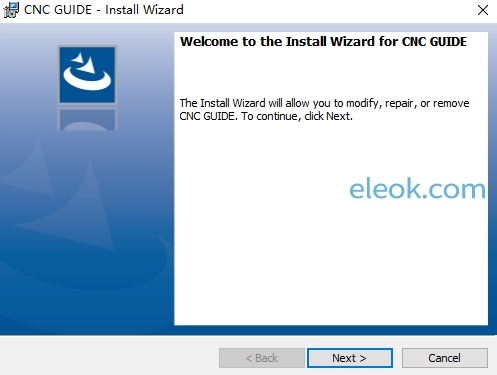

XX方法:首先运行NC GUIDE25_0_A08B-9010-K730目录下的安装程序,安装完毕后,如果是默认安装以windows10操作系统为例一般程序被安装到C:\Program Files (x86)\路径下的FANUC文件夹里,然后用NcGuidePatch25目录里的FANUC文件夹覆盖即可。

安装文件下载:仅提供个人在家学习用途,此程序文件来源于网络可靠性稳定性完整性皆无法验证,禁止用于其他用途,否则后果自负。

下载链接.txt

(1.45 KB)

下载链接.txt

(1.45 KB)

请先下载完文件后,再获取解压密码

解压密码.txt

(1.35 KB, 售价: 50 E币)

解压密码.txt

(1.35 KB, 售价: 50 E币)

注意:请确保您所用的网络可以访问百度网盘并能熟练使用百度网盘下载文件,若附件内下载链接失效不能下载,可以回复本文留下邮箱给您发送可用链接。

-------------------------------------------------------------------------

[01] About CNC GUIDE DVD

[02] Environment

[03] Install

[04] About Operator's Manual

[05] FANUC PICTURE function

[06] FOCAS2 function

[07] Restrictions

[08] Notes

[09] Update history

------------------------------------------------------------------------

=========================================================================

[01] About CNC GUIDE DVD

=========================================================================

The following software is stored in CNC GUIDE DVD.

- CNC GUIDE

- CNC Simulation function

- PMC Simulation function, Machine Simulation function

- ManualGuide i Simulation function

- FANUC PICTURE function

- FOCAS2 funtion

- Driver software of USB hardware Key

- Network license server software

=========================================================================

[02] Environment

=========================================================================

- When operating the CNC GUIDE

- Windows(R) 8.1 Pro (32bit,64bit)

Windows(R) 10 (32bit,64bit) Recommended Version 2004 or higher

+ .NET Framework2.0/.NET Framework 3.5

- Intel Core i3 or higher

- Memory 4Gbytes or more

- Vacant capacity of hard disk : 8.0Gbytes or more

- Display : 1280*1024(SXGA) or higher resolution

(Recommended 1920*1080(Full-HD) or higher resolution)

Dual display is recommended for iHMI mode.

- DVD drive

- USB port

- Network license server

* When you use the multi-user license by network, this software is necessary.

- Windows(R) 8.1 Pro (32bit,64bit)

Windows(R) 10 (32bit,64bit) Recommended Version 1803 or higher

Windows Server 2012 (64bit)

Windows Server 2012 R2 (64bit)

- Memory 2GB or more

- Vacant capacity of hard disk : 10Mbytes or more

- Display : 1024*768 or higher resolution

- DVD drive

- USB port

- Notes

1. In some cases, fully performance of this application can not be achieved

owing to the kind, performance and using condition of personal computer.

2. FANUC CNC GUIDE is under restriction of Windows as well as other

applications for Windows. So CNC GUIDE influences the performance of other

applications and also it is under the influence of other

applications.

3. Especially, it greatly influences the operation of the CNC GUIDE when a

real-time check with the anti virus software is effective.

4. When using FANUC LADDER-III or Machine Signal API function for PMC

simulation function, connecting to effective network or using a Loopback

Adapter is necessary.

Moreover, enabling the Hyper-Threading is recommended when using the FANUC

LADDER-III or the Machine Signal API function on the same PC that is using

the PMC simulation function.

5. In Windows(R) 10 Windows Update to the latest version is recommended.

In Windows(R) 10 version 1703 or older, CNC GUIDE operation may be slow.

6. Depending on the virtual environment, the hardware key may not be recognized

or CNC GUIDE may not work properly.

If you use CNC GUIDE in a virtual environment, use it on your own risk.

7. The hardware key may not be recognized on the remote desktop.

If you use CNC GUIDE on a remote desktop, use it on your own risk.

8. The UDP packet is transmitted when CNC GUIDE is used by the network license

and the network is communicated.

The UDP6001 port is used for the transmission.

When these communications cannot be done by the firewall software and

Switching hub, etc. , the function concerning the network license cannot

be used.

In that case, please set the firewall and Switching hub, etc. to

communicate.

9. Please don't install CNC GUIDE in PC for which other software that uses

the hardware key (protect key) has already been used.

When you install it, the hardware key might not be able to be recognized

correctly.

==========================================================================

[03] Install

==========================================================================

1. Procedure of install

(1) Set DVD in DVD drive.

(2) The installation is automatically begun.

(3) When the installation is not automatically begun,

"AutoRun.exe" that exists in the root folder of DVD is

double-clicked

from the Explorer and it starts.

(4) When NET Framework is not installed, .NET Framework installation is

begun. Please operate it according to the instruction of the screen.

(5) Select the installed software.

(6) The installation of the FANUC CNC GUIDE is begun.

Please operate it according to the instruction of the screen.

2. Attention for install

- Do not specify the root folder(\) for install folder.

Moreover, please do not use two byte character (Chinese character,

katakana, and Hangul, etc.) for the folder name.

- When CNC GUIDE in the PCs in which the CNC GUIDE that authorize

the license with the software license has been installed, it replaces

CNC GUIDE (Hardware key).

- Please do not install CNC GUIDE in the PC that the following software

installed.

+ CNC Simulator (A08B-9010-J720#ZZ11)

+ PMC Simulator (A08B-9210-J530#ZZ11)

+ ManualGuide i Simulator (A08B-9010-J540#ZZ11)

Please do the following work before installing the CNC GUIDE when these

software is installed.

(a)The CNC Simulator, the PMC Simulator, and ManuGuide i Simulator are

uninstalled.

(b)SSDCleanup11.exe is executed.(in \Setup\driver\Cleanup of DVD)

(c)The CNC GUIDE is installed.

==========================================================================

[04] About Operator's Manual

==========================================================================

The manual is included in the \doc folder of DVD as PDF file.

=========================================================================

[05] FANUC PICTURE function

=========================================================================

The following system is necessary to use FANUC PICTURE function on CNC GUIDE.

(1) For FS30i-A series

- FANUC PICTURE Disk (Japanese / English)(A08B-9010-J518#ZZ11)

(Edition 2.5 or later)

(2) For FS0i-D

- FANUC PICTURE Disk (Japanese / English)(A08B-9010-J518#ZZ11)

(Edition 3.1 or later)

The FP driver and the screen data for the sample of FANUC PICTURE are

included in CNC GUIDE DVD.

Please refer to the "Samples\FANUC PICTURE\Readme1.txt" for the use of the

sample.

=========================================================================

[06] FOCAS2 function

=========================================================================

The following system is necessary to use FOCAS2 function on CNC GUIDE.

(1) For FS30i-A series

- FOCAS1/2 Library disk(A02B-0207-K737) (Edition 3.2 or later)

(2) For FS0i-D

- FOCAS1/2 Library disk(A02B-0207-K737) (Edition 3.3 or later)

The libraries for test are included in CNC GUIDE DVD.

Please refer to the "Samples\FOCAS2\Readme2.txt" for the use of the libraries

for test.

==========================================================================

[07] Restrictions

==========================================================================

There are some restrictions in CNC GUIDE as follows.

(1) Two FANUC CNC GUIDE or more cannot be started at the same time.

(2) Display in monochrome mode is impossible.

(3) The boot screen and IPL menu screen cannot be displayed.

(4) The following size of the display is needed for the display without the

scroll of the whole of the FANUC CNC GUIDE for the size of the

CNC screen.

CNC screen size

10.4 inches: 1280*1024

15 inches: 2048*1536

The size of the display scrolls and uses the screen of the FANUC

CNC GUIDE less than this.

(5) The system construction that can be set is as follows.

[FS31i-A, FS31i-B]

Number of maximum machine groups: 3

Number of maximum path: 4

Number of maximum axes: 20

Number of maximum spindles: 6

[FS30i-B]

Number of maximum machine groups: 2

Number of maximum path: 4

Number of maximum axes: 20

Number of maximum spindles: 6

(6) About the parameter setting(ManualGuide i Simulation function)

Please do not change setting to the following parameters.

- Parameter No.14791#0=0

=========================================================================

[08] Notes

=========================================================================

(1) About the full screen display at the window mode

Full screen might not be able to be executed according to the kind of the

LCD display of the PC. These are hardware limitations.

The full screen correspondence can be confirmed on the BIOS screen when

the PC starts.

(2) About the file Delete by anti virus software false recognition

A case where "NCGuide.exe" included in this software is deleted

by anti virus software false recognition is confirmed.

In this case, file is deleted accidentally.

If the file is deleted, please follow the procedure below:

(a) Add the following folder to the scan exception settings for

antivirus software.

C:\Program Files (x86)\FANUC\NCGuide

(b) If "NCGuide.exe" is deleted, please carry out

the repair installation of CNC GUIDE after procedure (a).

=========================================================================

[09] Update history

=========================================================================

Ver 1.00(2006.9.11)

- First edition

Ver 2.00(2006.11.01)

- C language executor simulation function added

- Macro executor simulation function added

- The following problems are corrected.

+Warning is displayed at the return from the full-screen display

in the window mode

+Parameter NO.11412 or more cannot be punch and read.

+The path change cannot be executed by the operation from the PC key.

- Setting the memory card folder becomes possible.

The path is written in "< MEMCARD></MEMCARD >" of SimBaseSetting.xml.

Example) <MEMCARD>c:\ncguide_memcard</MEMCARD>

- The item was able to be displayed sorting and search in the option

setting tool.

- Update to CNC System Version 23.1

Ver 2.10(2006.12.25)

[NCGuide/NCGuidePro]

- The following problems are corrected.

+The display of version information is not correct.

[ManualGuide i]

- The customizing data can be arranged in the \user folder.

Arrangement in the '.\from' folder under the machine composition

folder was enabled.

(It is assumed that .\user folder is priority when there is a file

in both folders. )

- The speed of drawing on the screen has been improved.

- The following problems are corrected.

+ It hangs up when operating it when multi WIN is displayed.

[C language executor]

- The following problems are corrected.

+ If the putchar function is called, it becomes an error.

+ When the application is compiled, Warning of a double definition

of the O_RDONLY symbol is generated.

- The prototype declaration of the following function is added

to the header file.

os_get_chngappstr, crt_reguserchar_col, gr_dispfstr_col

Ver 2.20(2007.1.26)

[C language executor]

- It corresponds to save the variable of sramver.c.

Please refer to

"\doc\C language executor-About save the variables in sramver.c.pdf"

for details.

- It is corrected that the following function was returned because of

the error.

aux_file_mount, aux_file_unmount

Ver 2.30(2007.2.23)

[NCGuide/NCGuidePro]

- The following problems are corrected.

+ When English has been selected, Japanese message is displayed

in the key arrangement tool.

+ When 101/102 keyboards are used, cannot key input correctly.

+ When the split program list screen is displayed, SHIFT+Up/Down

cannot be operated.

+ It corresponds to operate the softkey by the click on the screen

at the picture mode.

- The full screen at the window mode might not be displayed according

to the PC, and the note is added to README.

- When "/MULTI_DISP" is specified for the argument of Simbase.exe

when the multi monitor is used, the NC guide is displayed in the

second monitor.

This function is effective only the picture mode.

- When the network license server is used, it is enabled that it is

environment variable NSP_HOST setting with PC that uses the NCGuide.

IP address of the license server is specified for environment

variable NSP_HOST.

The packet is sended only to the license server by this setting.

- "M30" is added at the program end of the machine configuration

setting "1path-3axis-M" of the sample.

[ManualGuide i]

- The following problems are corrected.

+ When the format of the memory card is executed, an illegal message

is displayed.

[C language executor]

- The following problems are corrected.

+ If the chdir function is used, the application error might be

occurred.

+ The current drive is not correctly changed by the chdrive function.

- Added mgi_jmp.h file.

[MACRO executor]

- Using key operation (SHIFT+1-5) for debugging function became

possible. (NGGuidePro Only)

Ver 2.40 (2007.3.27)

[NCGuide/NCGuidePro]

- The following problems are corrected.

+ When the machine composition setting is copied with the machine

composition setting tool, the folder for the machine composition

setting is not copied.

+ When the NC guide is executed after the machine composition

setting of the sample is deleted, installation CD is demanded.

+ When "/MULTI_DISP" displayed secondarily in the multi monitor is

started, it is not likely to be able to display it correctly.

+ It is likely not to operate correctly about environment variable

NSP_HOST correspondence.

+ The alarm history screen and the Maintenance information screen

were displayed.

It was corrected that it was not displayed.

- It corresponds to the memory card folder for each machine composition.

If "MEMCARD" folder is made for the folder for each machine

composition, the folder becomes the memory card folder of the machine

composition.

- The machine composition setting data protection function is added.

This function is used according to the function of the C language

executor.

- Option setting tool

When the function name name was searcheded, neither the capital letter

nor the small letter of the alphabet were distinguished.

- The following option was not registered.

Control axis detach, Tool geometry size data 100-pairs, 300-pairs

[C language executor]

- The following problems are corrected.

+ A mkdir and chdir function operate correctly.

+ The start argument for debugging "/CEXE_PAUSE" was able to be used

by the NCGuide.

It is possible to use it only by the NCGuidePro.

- It was corrected that kind setting of run time in the setting of

the Release build of the sample project was improper.

(Originally unnecessary DLL was needed. )

Before: RuntimeLibrary="2"

After: RuntimeLibrary="0"

[MANUAL GUIDE i]

- The following improvements are added.

+ The function of MANUAL GUIDE i BY70/23D version can be used.

+ The screen switch speed from NC screen to MANUAL GUIDE i screen

has been improved.

+ You can select execution mode of the machining simulation with

rotation tool.

No.27311#5=0 : Speed priority mode

No.27311#5=1 : Accuracy priority mode

- The following problems are corrected.

+ When NCGuide is reactivated, the color setting of tool path drawing

for the machining simulation is initialized.

+ In the memory card I/O function, it has been corrected not to

display the [FORMAT] soft key which did not work by the NC guide

+ The display of tool path falls into disorder when "Expansion,

Reduction or Rotation" of tool path drawing is operated.

+ NCGuide is not activated when the parameter No.14791#0 is set to 1.

+ Machining simulation is stopped at the waiting M code for each path

machining simulation (P27309).

Ver 2.50 (2007.6.29)

[PMC]

- The following improvements are added.

+ The function of PMC system software 40A0/18 version can be used.

+ The setting to hide the [PMC] menu is added on the Machine

composition setting window.

- The following problem is corrected.

+ The 1st ladder of Machine signal simulator did not work,

when the number of PMC path of PMC simulation function is one,

"PMC Memory-C" is selected, and 2nd and 3rd ladder of Machine

signal simulator are empty.

Ver 2.60 (2007.8.6)

[MANUAL GUIDE i]

- The following problems are corrected.

+ When X coordinate of start point is equal to X coordinate of end

point in the drawing during machining simulation, the small arc

segment is drawn as the round circular arc.

+ When one of basic three axes is set to the fourth axis and up,

machining simulation of MANUAL GUIDE i might not work correctly

after execution of cutter compensation.

Ver 2.70 (2007.10.29)

[NCGuide/NCGuidePro]

- The following improvements are added.

+ The following option was able to be assumed to be effective.

SPINDLE ANALOG OUTPUT FUNCTION, SPINDLE ANALOG OUTPUT FUNCTION

+ It corresponded to the license key making tool Ver2.0 for the

machine composition setting data protection function.

- The following problems are corrected.

+ The file list of the memory card is not displayed on the program

list and the ALL/IO screen.

+ The space character could not be input with PC keyboard.

+ When the focus exists in the MDI key window at the window mode,

the some keys("<>/*-+.()[]") could not be input.

[MANUAL GUIDE i]

- The following improvement is added.

+ The macro software of MANUAL GUIDE i is updated to the following

version.

BJ11/19

BH11/19

- The following problems are corrected.

+ When unit of data is inch, if the axis command of tilting tool is

executed in animated drawing in MANUAL GUIDE i, a tool is drawn by

the tilt of only 1/10 of the command.

+ In case of setting the C axis an axis parallel to the Y axis, when

an arc was made by the contour programming in ZC plane at MANUAL

GUIDE i, the circular command with reverse rotation was outputted

to program memory.

[C language executor]

- The following problems are corrected.

+ In the realloc function of C Language Executor, if the specified

DRAM memory size is larger than the one actually allocated by the

application, the specified size of DRAM memory is allocated.

+ In the following functions of C Language Executor, even if the

value is read/write specifying the memory address of the PMC data

directly, the value cannot read/write correctly.

pmc_rdpmcchar

pmc_wrpmcchar

[MACRO executor]

- The following problems are corrected.

+ The position of the screen click to operate a soft key was not

correct at the 15inch screen mode.

+ The loading was not able to be done correctly when the MEM file

of MACRO executor was a specific size occasionally.

Ver 2.80 (2007.11.22)

[MACRO executor]

- The following problems are corrected.

+ When the LCD size is selected 15 inches, right five softkeys can't

be operated.

[MANUAL GUIDE i]

- The following improvements are added.

+ MANUAL GUIDE i function has been updated to the function equivalent

to system software BY70/26A.

+ The following functions can be changed to active or inactive by

a parameter.

Milling cycle, Turning cycle, Animation

Ver 2.90 (2008.04.07)

[NCGuide/NCGuidePro]

- The following problems are corrected.

+ It was corrected to the following option number.

SERIAL SPINDLE INTERFACE : J850

SPINDLE ANALOG OUTPUT FUNCTION : J860

+ Tool offset function might not work correctly.

[C language executor]

- The following improvements are added.

+ The following functions are added.

cnc_rdtlgeomsize_ext (read Tool geometry size data)

cnc_wrtlgeomsize_ext (write Tool geometry size data)

Ver 2.92 (2008.07.17)

[NCGuide/NCGuidePro]

- The following improvements are added.

+ Parameter No.1815#5(APC) was invalidated.

Ver 3.00 (2008.08.04)

[NCGuide/NCGuidePro]

- Update to CNC System Version G111/49.0,G113/32.0

- It corresponded to the following G code.

G77 (turning cycle)

G78 (screw cycle)

- Apply to FANUC PICTURE for NCGuidePro.

- Apply to FOCAS2 for NCGuidePro.

- The following options were able to be used.

TURKISH DISPLAY

RUSSIAN DISPLAY

SELECTION OF FIVE OPTIONAL LANGUAGE

TOOL MANAGEMENT EXPANSION B

TOOL ATTACHMENT /DETACHMENT MANAGEMENT FUNCTION

[MANUAL GUIDE i]

- The following improvements are added.

+ MANUAL GUIDE i function has been updated to the function equivalent

to system software BY70/30.

- The following problems are corrected.

+ In the machining simulation of MANUAL GUIDE i, a hole on

cylindrical surface was not cut correctly when the animated

drawing by a milling tool was performed in giving priority to

cutting off (Parameter No.27311#5=1).

[C language executor]

- The following improvements are added.

+ The size of DRAM memory that can be used in C Executor has been

expanded up to 8MB.

+ Displaying and reading Turkish message is available.

+ Displaying and reading Russian message is available.

+ The following functions are added.

cnc_chglang (Switches the display language on the CNC screen)

cnc_rdmag_property (Read the magazine property data)

cnc_wrmag_property (Write the magazine property data)

cnc_delmag_property (Delete the magazine property data)

cnc_rdpot_property (Read the pot property data)

cnc_wrpot_property (Write the pot property data)

cnc_delpot_property (Delete the pot property data)

cnc_rdparainfo (Read parameter data information)

cnc_machine3 (Read machine position of controlled axis (3))

cnc_rdjogdrun (Read jogging speed or dry run speed)

cnc_confirm_restart

(Confirmation for restarting after program editing)

cnc_prot_pswinp (Sets/changes the operation level)

cnc_prot_pswcan

(Changes the operation level to a level from 0 to 3)

cnc_prot_pswchg (Changes the operation level password)

cnc_prot_pswinit (Initializes the operation level password)

cnc_wrprt_lvl

(Changes the change protection level/output

protection level of each data item)

os_getmemstatus (Read the heap memory information)

Ver 4.00 (2008.09.12)

[NCGuide/NCGuidePro]

- The FS0i-D version was added.

It is possible to use this with the hardware key since the Ver4.0.

[PMC]

- The following improvements are added.

+ The function of PMC system software 40A0/22 version can be used,

including "Function Block function".

Ver 4.10 (2009.01.16)

[NCGuide/NCGuidePro]

- The option list of FS31i version that existed in the manual was

corrected.

[C language executor]

- The following problems are corrected.

+ Hang up might occur at the step execute when the application is

debugged.

[MANUAL GUIDE i]

- The following improvements are added.

+ MANUAL GUIDE i function has been updated to the function equivalent

to system software BY70/35.

Ver 4.20 (2009.04.16)

[NCGuide/NCGuidePro]

- The package for the update was added.

1)NCGuide(Upgrade for addition of CNC model:1-30Users)

A08B-9010-J740 - J743#ZZ11

2)NCGuidePro(Upgrade for addition of CNC model:1-30Users)

A08B-9010-J745 - J748#ZZ11

3)NCGuide/NCGuidePro(Upgrade for CNC software)

A08B-9010-J750#ZZ11

- The hardware key upgrade tool was added.

- The following problems are corrected.

+ It was corrected that real feed speed had not been correctly

displayed. (FS31i version )

+ It was corrected might the generation of the application

exception in the during starting.

[C language executor]

- The following options have been available.

NONVOLATILE MEMORY EXPANSION 64K

NONVOLATILE MEMORY EXPANSION 256K

[PMC]

- The following problems are corrected.

+ In FS0i-D, Ladder step option included in "Package 1" or

"Package 2" could not be enabled correctly.

+ SET/RST instructions in Common Line Control area (COM - COME) could

not be correctly controlled by ACT signal of COM instruction.

+ In FS31i-A or FS0i-D,if only PMC Simulation Function is

enabled, options could not be changed.

Ver 4.30 (2009.12.01)

[NCGuide/NCGuidePro]

- Update to CNC System Version G114/16.0

- NCGuide/NCGuidePro might not start or run very slowly by the

influence of other applications like the anti virus software etc.

In that case, the level of the timer is set to SimBaseSetting.xml

as follows.

Example) <TIMER_LEVEL>3</TIMER_LEVEL>

The value from 3 to 10 can be set to this setting.

This value is 2 when the unset.

The influence can be evaded by setting 3 or 4 usually.

- The following options were able to be used.

TILTED WORKING PLANE COMMAND WITH GUIDANCE

FLEXIBLE PATH AXIS ASSIGNMENT

- The application error might generate NCGuide/NCGuidePro in the during

starting. (The problem of WindowsOS is a cause. )

In that case, the following error is output to log file(log\SIM.LOG).

at System.Diagnostics.NtProcessManager.GetProcessInfos

(PerformanceCounterLib library)

It was corrected that this error did not occur.

[PMC]

- The following improvements are added.

+ In FS31i-A, the function of PMC system software 40A0/25

version can be used.

+ In FS0i-D, the function of PMC system software 40B0/02

version can be used.

[C language executor]

- The following improvements are added.

+ In FS31i-A, the following functions are added.

crt_chgvskpage (Change a page of one-touch menu)

gr_dispvskmenu (Get the screen number and draw the vertical

soft key character string)

cnc_pdf_rdmainpt (Read executing block number of main program)

+ In FS31i-A, when accessing the memory card by specifying

drive C, the following functions have been available.

fseek, lseek, ftell, tell, feof, eof, fgetpos, fsetpos, rename,

rewind, getcwd, _chdrive, _getdrive, _dos_getdiskfree

+ In FS31i-A, the following functions have been available.

mkdir, rmdir, chdir

- The following problem is corrected.

+ In FS31i-A, when the _dos_getdiskfree function is executed,

- When "1" is specified for the argument, information on not SRAM

disk but drive A of the personal computer is acquired.

- When "2" is specified for the argument, information on not

memory card but drive B of the personal computer is acquired.

- When "3" is specified for the argument, information on not

memory card but drive C of the personal computer is acquired.

Ver 4.40 (2010.04.01)

[NCGuide/NCGuidePro]

- It works and support for following Windows Operating system.

Windows(R) Vista Business, Windows(R) 7 Professional

- G code skip function was added. (FS31i version )

- The following problems are corrected.

+ It was corrected that feedrate command value and real feed speed was

defferent. (FS31i version )

+ It was corrected that when NCGuide or NCGuidepro started with mode

of selecting machine composition, the machine composition selection

was canceled and application error occurred.

exception in the during starting.

[MANUAL GUIDE i]

- The following problems are corrected.

+ When a groove for turning cycle has step figure and is machined

by dividing in some layers, residual part might be left.

Ver 4.50 (2010.07.01)

[NCGuide]

- Academic package was added.

1)for Classroom A08B-9010-J751#ZZ11

2)for Homework A08B-9010-J752#ZZ11

- Apply to conversational macro screen for 8.4 inch display.

(for FS31iA version)

[MANUAL GUIDE i]

- The following problems are corrected.

+ The value of the tool data base is not saved.

Ver 5.00 (2010.11.01)

[NCGuide/NCGuidePro]

- The FS31i-B and FS35i-B version was added.

It is possible to use this with the hardware key since the Ver5.0.

- Machine Operator's Panel was added. (NGGuidePro Only)

- The following problems are corrected.

+ The diagnosis operation of the license authentication setting tool

might fail.

+ A hardware key cannot be updated.

[C language executor]

- "C-language Executor Library (for conversion from PMC C-language)"

for NCGuide/NCGuidePro was added in the sample.

[MANUAL GUIDE i]

- The following improvements are added.

+ In FS31i-B, the function of MANUAL GUIDE i system software

BX71/02version can be used.

+ In FS31i-A, MANUAL GUIDE i function has been updated to the

function equivalent to system software BY70/44.

+ In FS0i-D, MANUAL GUIDE i function has been updated to the

function equivalent to system software BX32/10.

Ver 5.10 (2011.04.15)

[NCGuide/NCGuidePro]

- It works and support for following Windows Operating system.

Windows(R) 7 Professional 64bit

- The following options were able to be used.

CONSTANT SURFACE SPEED CONTROL

INTERRUPTION TYPE CUSTOM MACRO (FS31i-B)

- The following problems are corrected.

+ At program list screen or all I/O screen, even if all files in

MEMCARD are deleted, the last file cannot be deleted.

+ When the display language of invalid option is selected,

NCGuide/NCGuidePro doesn't start.

Ver 5.20 (2011.06.08)

- The following problems are corrected.

+ When the customizing function of MANUAL GUIDE i is used,

NCGuide/NCGuidePro doesn't sometimes start.

+ The installation of the NCGuide Academic package fails.

Ver 5.30 (2011.06.30)

- The following options were able to be used.

MULTI-STEP SKIP FUNCTION (FS31i-B)

INTERRUPTION TYPE CUSTOM MACRO (FS0i-D)

- The following problems are corrected.

+ The coordinate of a rotary axis is illegal during cylindrical.

+ NCGuide/NCGuidePro might fail to start up in the environment with

plural network adaptors.

+ The dialog displayed when selecting it to install SB7 might be

hidden to the back side of the installer.

Ver 6.00 (2011.10.31)

[NCGuide/NCGuidePro]

- The FS31i-LB and FS35i-PB version was added.

It is possible to use this with the hardware key since the Ver6.0.

- Update to CNC System of FS31i-B Version G411/15.0

- The following options were able to be used.

FANUC PICTURE EXECUTOR (FS31i-B)

- In FS35i-B, 15 inch display was able to be used.

- The following problems are corrected.

+ The address written by real-time custom macro is illegal. (FS31i

-B)

+ When Max. number of simultaneously displayed axes is 10 or more,

offset screen is displayed and application error occurred.

Ver 6.10 (2011.12.09)

[NCGuide/NCGuidePro]

- The following options were able to be used.

Extended conversational macro function (FS31i-B)

Extended conversational macro function (option) is a function

that makes FS20i-B macro program an acutuate way with

FS30i/31i/32i-B.

The following instructions become available by this option.

+ Window display (G270, G271)

+ Display of external characters at any position (G281)

+ Shift and scale in the graphic coordinate system (G208)

This option is available in 8.4" display unit only.

(Refer to "Macro Executor for Series20i" of the appendix of

Programming Manual (B-61803E-1) for details. )

- The following problems are corrected.

+ When files in memorycard are displayed at PMC data I/O screen,

NCGuide/NCGuidePro is turned off illegally. (FS31i-B)

[MANUAL GUIDE i]

- The following improvements are added.

+ In FS31i-B, MANUAL GUIDE i function has been updated to the

function equivalent to system software BX71/06.

+ In FS31i-A, MANUAL GUIDE i function has been updated to the

function equivalent to system software BY70/47.

+ In FS0i-D, MANUAL GUIDE i function has been updated to the

function equivalent to system software BX32/13.

- The following function were able to be used.

Set-up guidance functions

Ver 6.11 (2012.03.01)

[NCGuide/NCGuidePro]

- Update to CNC System of FS31i-B Version G411/23.0

- The following options are added.

Optional block skip (FS31i-B)

- The following improvements are added.

+ In Lathe/Machining center G code system switching function, the

parameter No.25595 that changes the order of the display of the

axis on position display screens has been added. (FS31i-B)

+ When lathe/machining center G code system is switched, the

parameter No.13000#4 which cancels command for maximum spindle

speed clamping has been added. (FS31i-B)

- In the screen of tool offset for milling and turning function,

the following improvement has been added.

+ Tool number display

+ Guidance display for imaginary tool nose

+ Switching protection of geometry/wear offset by soft key operation

+ Prohibition against cursor movement to protected item

- In the tool geometry size data setting screen,

the following improvement has been added.

+ Tool number display

+ Coordinate axis display in guidance

Ver 6.20 (2012.06.01)

[NCGuide/NCGuidePro]

- Update to CNC System of FS31i-LB Version G4C1/13.0

- Update to CNC System of FS31i-PB Version G4E1/12.0

- The movement of the window has been enabled at the picture mode.

[MANUAL GUIDE i]

- The following screens are able to be used.

+ Setting Window of offset number and tool number

+ Tool Management Data Window

+ Tool Life Data Screen

+ Tool Life Data List Screen

- The following problem is corrected.

+ When MANUAL GUIDE i is effective,

the application exception might occur in rare cases.

Ver 6.30 (2012.06.22)

[PMC]

- In FS31i/35i-B and FS31i-LB/PB, Machine Signal simulator

function has become available.

- In FS31i/35i-B and FS31i-LB/PB, PMC Simulation function has

been updated to correspond to 40A5/09.

(except Ladder dividing management function)

Ver 6.32 (2012.09.07)

[NCGuide/NCGuidePro]

- The following problems are corrected.

+ The message of macro alarm is illegal displayed on the alarm

history screen. (FS31i-B)

+ In the program word editing function, the word which first

character is '[' can not be input. (FS31i-A)

+ The wrong value is returned by cnc_statinfo2() with Ethernet

connection. (FS31i-A, FS0i-D)

[MANUAL GUIDE i]

- The following improvements are added.

+ In FS31i-B, MANUAL GUIDE i function has been updated to the

function equivalent to system software BX71/08.

+ In FS31i-A, MANUAL GUIDE i function has been updated to the

function equivalent to system software BY70/49.

+ In FS0i-D, MANUAL GUIDE i function has been updated to the

function equivalent to system software BX32/15.

- The following problem is corrected.

+ Hang up might occur at cycle input screen.

Ver 7.00 (2012.10.01)

[NCGuide/NCGuidePro]

- FS32i-B Function for transfer line was added.

It is possible to use this with the hardware key since the Ver7.0.

The installer is different from other CNC model.

Please use the following installer.

(DVD):\Setup\NCGuide_Line\en\setup.exe

Operator's manual is the following file.

(DVD):\doc\NCGuide,NCGuidePro Function for transfer line.pdf

- Update to CNC System of FS31i-B Version G411/32.0

- The following problems are corrected.

+ If the move command of chopping axis is specified after chopping

cancel (G80), the movement of the chopping axis might not start.

(FS31i-A/B)

[PMC]

- In FS31i-B, FS31i-LB/PB, and FS32i-B Function for transfer line,

Ladder dividing management function has been supported.

Ver 7.01 (2012.12.14)

- The following options were able to be used.

PERIPHERAL AXIS CONTROL (FS31i-B)

EMBEDDED MACRO (FS31i-B)

Ver 8.00 (2013.04.15)

- The FS30i-B G311/35.0 version was added.

It is possible to use this with the hardware key since the Ver8.0.

- Update to CNC System of FS31i-B Version G411/35.0

- In FS31i-A/-B, the build environment of C Language Executor

application has been updated to the function equivalent to Series

30i C Language Libraly for C Language Executor GZ0I/5.9.

- The maximum number of servo axis and spindles has been enhanced.

(FS0i-D)

- The following options were able to be used.

SMOOTH INTERPOLATION (FS31i-B)

NURBS INTERPOLATION (FS31i-B)

SMOOTH TCP (FS31i-B)

TOOL CENTER POINT CONTROL (FS31i-MOD B)

MACHINE CONFIGURATION SELECTING FUNCTION (FS31i-B)

3 DIMENSIONAL CIRCULAR INTERPOLATION (FS31i-B)

MACHINING QUALITY LEVEL ADJUSTMENT (FS31i-B)

3-DIMENSIONAL MANUAL FEED (FS31i-B)

MACHINING CONDITION SELECTING FUNCTION (FS31i-B)

3-DIMENSIONAL CUTTER COMPENSATION (FS31i-B)

INCLINED ROTARY AXIS CONTROL (FS31i-B)

PROGRAMMABLE RAPID TRAVERSE OVERLAP (FS31i-B)

NANO SMOOTHING (FS31i-B)

WORKPIECE SETTING ERROR COMPENSATION (FS31i-B)

- The following problems are corrected.

+ Only low-order 1 byte of signal is written by word-by-word or

double word-by-double word in real-time custom macro function.

Ver 8.01 (2013.04.23)

- The following problems are corrected.

+ When Peripheral Axis Control is enabled, the offset does not work

even if the tool offset instruction in lathe systems.

Ver 8.02 (2013.08.05)

- Update to CNC System of FS0i-D Version 30.0.

- The option diagnose was enabled.

- The following options were able to be used.

MANUAL HANDLE FEED 1-UNIT (FS0i-D, FS30i-B, FS31i-B)

MANUAL HANDLE FEED 2/3-UNITS (FS0i-D, FS30i-B, FS31i-B)

[MANUAL GUIDE i]

- The following improvements are added.

+ In FS31i-B, MANUAL GUIDE i function has been updated to the

function equivalent to system software BX71/11.

+ In FS31i-A, MANUAL GUIDE i function has been updated to the

function equivalent to system software BY70/52.

+ In FS0i-D, MANUAL GUIDE i function has been updated to the

function equivalent to system software BX32/18.

- The following problem is corrected.

+ A part of message defined with the user customizing file might be

lacked and it be displayed.

Ver 8.10 (2013.08.30)

- Update to CNC System of FS35i-B Version G601/12.0.

- The following improvements are added.

+ The parameter TZ1, TZ2, TZ3(No.11851#2, No.11852#2, No.11853#2) has

been added.

It changes the number of tool offset value in Peripheral axis

control to zero. (FS31i-B)

- The following options were able to be used.

ADDITION OF CUSTOM MACRO COMMON VARIABLES 1000 (FS30i-B, FS31i-B)

[C language executor]

- The following improvements are added.

+ In FS0i-D, the following functions have been available.

mkdir, rmdir, chdir

- The following problem is corrected.

+ In FS0i-D, when the _dos_getdiskfree function is executed,

- When "1" is specified for the argument, information on not SRAM

disk but drive A of the personal computer is acquired.

- When "2" is specified for the argument, information on not

memory card but drive B of the personal computer is acquired.

Ver 8.11 (2014.02.03)

+ In Milling's Tool length compensation of Tool offset for milling

and turning function, the parameter bit 7 (ZBO) of No.25581 that

selects the setting of always using the compensation value of

Z-axis/length has been added. (FS30i-B, FS31i-B, FS32i-B)

[MANUAL GUIDE i]

- The following improvements are added.

+ High speed of the display of the life management data list screen

is done.

+ Measurement cycle used with 18i-TB can be enabled in FS31i-B.

- The following problem is corrected.

+ The problems related to manual measurement and measurement cycle.

Ver 9.00 (2014.06.30)

- The NCGuidePro was integrated into the NCGuide.

(NCGuidePro were removed after this.)

- Update to CNC System of FS30i-B Version G311/56.0.

- Update to CNC System of FS31i-B Version G411/56.0.

- The following options were able to be used.

[FS30i-B, FS31i-B]

+ Custom macro variable name 31 characters(R583)

+ Nozzle compensation(R567)

+ Virtual MDI key(S883)

+ Machine State Monitoring Function(R717)

[FS30i-B, FS31i-B, FS0i-D]

+ Software operator's panel(J960)

+ Software operator's panel general purpose switch(J961)

- The following improvements are added.

+ The display of feedrate is improved when

acceleration/deceleration before interpolation was enabled.

+ After the old version is uninstalled when the old version is

installed, the installation is done.

- The following problem is corrected.

+ When the file extension is a small letter, the file cannot be read.

+ The switch to an illegal screen is occurred by RESET key input on

the program screen when the program restart option is effective.

[PMC]

- PMC simulation function of FS0i-D has been updated to be equivalent

to 40B0/11.

- The following options have been available:

[FS0i-D]

+ Ladder step Max.64,000 steps (Package 1 / R006#64K)

+ Ladder step Max.24,000 steps (Package 2 / R002#24K)

[FS32i-B Function for transfer line]

+ Step sequence function (S982)

- The following improvements have been applied:

+ Main and sub panel windows of Standard Machine Operator's Panel can

be minimized also in picture mode.

- The following problems have been corrected.

+ The size of I/O operation panel might change at start up.

Ver 9.01 (2014.09.30)

- The following problems are corrected.

+ Cycle Time Estimate Function is not correctly installed.

Ver 9.10 (2014.11.17)

- The following kind was added to the Academic Package.

+ for Classroom(32 Users) A08B-9010-J761#ZZ12

+ for Homework(3 Years) A08B-9010-J762#ZZ12

- The following options were able to be used at the Academic Package.

[FS30i-B, FS31i-B, FS31i-A, FS0i-D]

+ Macro Executor

+ C-language Executor

+ FANUC picture

Ver 10.00 (2015.02.05)

- The FS0i-F/4.0 version was added.

- The following options were able to be used at the Academic Package.

[FS31i-A, FS30i-B, FS31i-B, FS35i-B]

+ FANUC AUTO HMI-NC (R572)

+ FANUC AUTO HMI-NC screen enhancement 1 (R653)

[PMC]

- PMC simulation function of FS30i-B has been updated to be equivalent

to 40A5/19.

[MANUAL GUIDE i]

- The following improvements are added.

+ In FS31i-B, MANUAL GUIDE i function has been updated to the

function equivalent to system software BX71/14.

+ In FS31i-A, MANUAL GUIDE i function has been updated to the

function equivalent to system software BY70/55.

+ In FS0i-F, MANUAL GUIDE i function (equivalent to system

software BX33/02) was added.

+ In FS0i-D, MANUAL GUIDE i function has been updated to the

function equivalent to system software BX32/21.

- The following problem is corrected.

+ Hang up might occur when arbitrary free figure of cycle is

drawn in base screen.

Ver 11.00 (2015.10.19)

- C language executor application protection function was added.

- Update to CNC System of FS30i-B Version G311/74.0.

- Update to CNC System of FS31i-B Version G411/74.0.

- The following options were able to be used.

[FS30i-B]

+ 5-Axis Machining Condition Setting Function(R721)

[FS30i-B, FS31i-B]

+ CNC Screen Display for 19"LCD(R624)

[FS0i-F]

+ Function for Loader Control(R417)

+ Addition of Loader Control Path(R418)

- The FS31i-WB/14.0 version was added.

[PMC]

- PMC simulation function of FS30i-B has been updated to be equivalent

to 40A5/21.

Ver 12.00 (2016.04.28)

- The FS30i-B which supports iHMI function was added.

However, only 15-inch of picture mode is supported.

Therefore, depending on the resolution of the display, NCGuide may not

fit in the display.

If the entire of NCGuide is displayed, it is recommended to set the

folloing resolution of the display.

Resolution: 2048 * 1536 (QXGA)

- Update to CNC System of FS31i-WB Version G4A1/15.0.

- The following options were able to be used.

[FS30i-B, FS31i-B]

+ Spindle Orientation (J853)

+ Spindle Output Switching Function (J854)

+ Extended Spindle Orientation (J861)

+ Extended Spindle Output Switching Function (J862)

The above function supports the signal only.

[FS31i-LB]

+ T-axis and C-axis Simultaneous Control (S907)

+ Addition Of Cutting Condition Data (S912)

[FS31i-PB]

+ T-axis and C-axis Simultaneous Control (S907)

- The following improvements have been applied:

+ Operation history was supported. (FS30i-B, FS31i-B)

+ C language executor function for reading and writing of PMC parameter was

supported. (FS30i-B, FS31i-B)

+ Hindi language was supported. (8.4 inch display of FS0i-F)

+ Spindle speed and motor speed in consideration of the S command and

the gear ratio is displayed on the spindle monitor screen.

(FS30i-B, FS31i-B)

+ Blank is displayed on each spindle information of the spindle

information screen.(FS30i-B, FS31i-B)

- The following problem is corrected.

+ The wire option can not be set on FS31i-WB.

[PMC]

- The function of save/restore X signal state was added.

- The signal operation replay function is improved.

(According to each machine configuration, the folder path for

the signal operation file is changed.)

- The function of key top customization of main panel was added.

- The display of only main panel for the standard machine operator's

panel is applied.

Ver 12.10 (2016.07.29)

- CNC System of FS30i-B was updated to version G311/84.0.

- CNC System of FS31i-B was updated to version G411/84.0.

- CNC System of FS30i-B iHMI was updated to version G311/84.0.

- iHMI application of FS30i-B iHMI was updated to version 3.0.

- The following options were able to be used.

[FS30i-B, FS30i-B iHMI, FS31i-B]

+ Gentle normal direction control (J986)

- The following improvements have been applied:

+ Window mode was added to display mode. (FS30i-B iHMI)

+ 10.4 inch and 19 inch were added to CNC display size. (FS30i-B iHMI)

+ Protection key signal was able to be used. (FS30i-B, FS31i-B)

+ Several options can be set in a single file at option setting tool.

(FS30i-B, FS30i-B iHMI, FS31i-B)

+ Operator's panel was added at window mode.

[PMC]

- PMC simulation function of FS30i-B has been updated to be equivalent

to 40A5/24.

- PMC simulation function of FS0i-F has been updated to be equivalent

to 40B2/05.

Ver 12.11 (2016.09.13)

- Touch panel operation became provisional possible. in C language executor

function.

Ver 13.00 (2016.11.30)

- FS31i-B5 was added.

- CNC System of FS30i-B was updated to version G311/86.0.

- CNC System of FS31i-B was updated to version G411/86.0.

- iHMI application of FS30i-B iHMI was updated to version 6.0.

- The following options were able to be used.

[FS30i-B, FS30i-B iHMI, FS31i-B]

+ 3D interference check with personal computer function (R542)

- The following problem was corrected.

+ The Option Setting dose not start without Excel 2010 installed.

(FS30i-B, FS30i-B iHMI, FS31i-B)

Ver 14.00 (2017.02.22)

- Power Motion i-A(PMi-A) was added.

- CNC System of FS30i-B and FS30i-B iHMI were updated to version G311/90.0.

- CNC System of FS31i-B was updated to version G411/90.0.

- CNC System of FS0i-F was updated to version 28.0.

- iHMI application of FS30i-B iHMI was updated to version 9.2.

- Floating point functions of PMC was able to be used.(FS0i-F)

- The following options were able to be used.

[FS30i-B, FS30i-B iHMI, FS31i-B]

+ Smooth tolerance control(R696)

+ Multi-path editing function(R615)

Ver 15.00 (2017.05.28)

- FS32i-B was added.

- CNC System of FS30i-B and FS30i-B iHMI were updated to version G311/93.0.

- CNC System of FS31i-B was updated to version G411/93.0.

- CNC System of FS0i-F was updated to version 32.0.

- iHMI application of FS30i-B iHMI was updated to version 11.0.

- Manual Guide i System of FS31i-A was updated to version BY70 / 62.

- Manual Guide i System of FS30i/31i-B and FS30i-B iHMI was updated to version BX72 / 04.

- Manual Guide i System of FS0i-D was updated to version BY32 / 29.

- Manual Guide i System of FS0i-F was updated to version BY33 / 11.

- The following options were able to be used.

[FS30i-B, FS30i-B iHMI, FS31i-B]

+ 3-dimensional tool compensation(J727)

+ Tool offset conversion function(R691)

+ Quick program restart(R630)

+ The number of custom macro variable name 1000(R323)

+ The number of custom macro variable name 4000(R324)

- The following improvements have been applied:

+ "Picture Mode - Horizontal" was display mode.

Ver 15.10 (2017.07.31)

- CNC System of FS30i-B and FS30i-B iHMI were updated to version G311/97.0.

- CNC System of FS31i-B was updated to version G411/97.0.

- CNC System of FS31i-B5 was updated to version G431/97.0.

- CNC System of FS32i-B was updated to version G501/97.0.

- CNC System of FS0i-F was updated to version 35.0.

- iHMI application of FS30i-B iHMI was updated to version 12.1.

- The following options were able to be used.

[FS30i-B, FS30i-B iHMI, FS31i-B]

+ Groove cutting function by continuous circle movement(S854)

[FS30i-B, FS30i-B iHMI, FS31i-B, FS32i-B]

+ High speed program check(S880)

+ High precision oscillation function(R662)

+ Tool management function for multi-edge tools(R681)

Ver 15.20 (2017.10.31)

- CNC System of FS30i-B and FS30i-B iHMI were updated to version G311/99.0.

- CNC System of FS31i-B was updated to version G411/99.0.

- CNC System of FS31i-B5 was updated to version G431/99.0.

- CNC System of FS32i-B was updated to version G501/99.0.

- CNC System of FS0i-F was updated to version 37.0.

- CNC System of FS31i-LB was updated to version G4C3/14.0.

- CNC System of FS31i-PB was updated to version G4E1/36.0.

- iHMI application of FS30i-B iHMI was updated to version 14.3.

- The following options were able to be used.

[FS31i-B]

+ High-speed Smooth TCP(R677)

[FS31i-LB]

+ 2 LASERS CONTROL FUNCTION(S911)

Ver 15.30 (2018.01.15)

- The following problems are corrected.

+ Switching from C language executor screen or Manual Guide i screen

to CNC screen is not possible. (FS0i-F)

Ver 15.40 (2018.06.22)

- CNC System of FS30i-B and FS30i-B iHMI were updated to version G31A/07.0.

- CNC System of FS31i-B was updated to version G41A/07.0.

- CNC System of FS31i-B5 was updated to version G43A/07.0.

- CNC System of FS32i-B was updated to version G50A/07.0.

- CNC System of FS0i-F was updated to version 44.0.

- The sample ladder program of PMi-A was applied to the standard machine operator's panel.

- The following options were able to be used.

[FS30i-B iHMI]

+ iHMI set-up guidance (R910)

+ iHMI machining cycle (for 1 path system) (R911)

+ iHMI machining cycle (for 2 path system) (R912)

+ iHMI machining cycle (for 3 path system) (R913)

+ iHMI machining cycle (for 4 path system) (R914)

Ver 15.50 (2018.12.26)

- CNC System of FS30i-B and FS30i-B iHMI were updated to version G313/12.0.

- CNC System of FS31i-B was updated to version G413/12.0.

- CNC System of FS31i-B5 was updated to version G433/12.0.

- CNC System of FS32i-B was updated to version G503/12.0.

- CNC System of FS0i-F was updated to version D4G2(D6G2)/13.0.

- iHMI application of FS30i-B iHMI was updated to version 23.0.

- Added Machine Composition Creation Tool for FS30i/31i/32i-B.(Excluding Academic package)

- Added the function to launch NCGuide by double-clicking the Machine composition setting data.

- The following options were able to be used.

[FS30i-B, FS30i-B iHMI, FS31i-B, FS31i-B5]

+ HIGH-SPEED CYCLE MACHINING

+ High-speed cycle machining(J833)

+ High-speed cycle machining retract function(J663)

+ High-speed cycle machining skip function(S662)

+ High-speed cycle machining operation information(R609)

+ Spindle control switching function for high-speed cycle machining(R608)

+ High-speed cycle cutting additional variables A(J745)

+ High-speed cycle cutting additional variables B(J746)

+ High-speed cycle cutting additional variables C(S640)

+ High-speed cycle cutting additional variables D(R513)

[FS31i-B]

+ Cutting point command(S996)

[FS32i-B]

+ High-speed processing(S809)

+ Addition of workpiece coordinate system 300-pairs(J919)

[FS30i-B, FS30i-B iHMI, FS31i-B, FS31i-B5, FS32i-B, FS0i-F, FS31i-LB, FS31i-PB, FS31i-WB, FS32i-B LINE]

- Running speed of CNC simulation function was closer to the actual CNC.

- Fixed an issue that may work slowly or may not work under Windows(R) 10 version 1703 or older.

Ver 15.51 (2019.1.12)

- The connectivity with FANUC LADDER-III and FOCAS2 on PC with two or more networks has been improved.

[FS0i-D, FS30i-A, FS35i-B, PMi-A]

- Running speed of CNC simulation function was closer to the actual CNC.

- Fixed an issue that may work slowly or may not work under Windows(R) 10 version 1703 or older.

[PMC]

- PMC simulation function of FS30i-B has been updated to be equivalent to 40A7/01.

- PMC simulation function of FS0i-F has been updated to be equivalent to 40B4/02.

Ver 16.00 (2019.4.23)

- FS0i-F Plus was added.

CNC System is version D4G3(D6G3) / 01.

Manual Guide i System is version BY34 / 11.

- CNC System was updated to following series / version.

+ FS30i-B iHMI : G313 / 22

+ FS30i-B : G313 / 22

+ FS31i-B : G413 / 22

+ FS31i-B5 : G433 / 22

+ FS32i-B : G503 / 22

- iHMI application of FS30i-B iHMI was updated to version 29.0.

- Manual Guide i System was updated to following series / version.

+ FS30i-B : BX72 / 14

+ FS31i-B : BX72 / 14

+ FS31i-B5 : BX72 / 14

+ FS31i-A : BY70 / 70

+ FS0i-F : BX33 / 21

+ FS0i-D : BX32 / 36

- Flat design and dark gray display ware supported in FS0i-F.

- The following options were able to be used.

[FS30i-B, FS30i-B iHMI, FS31i-B, FS31i-B5, FS32i-B, FS0i-F]

+ Multi-language display Slovenian(R320)

+ Multi-language display Bulgarian(R686)

+ Multi-language display Rumanian(R694)

+ Multi-language display Slovak(R693)

+ Multi-language display Finnish(R726)

+ Multi-language display Vietnamese(R410)

+ Multi-language display Indonesian(R411)

+ Manual Guide i Extended axis name function(S789)

+ Manual Guide i advanced guidance function(S774)

+ C-language executor additional SRAM 512KB(S827)

[FS30i-B, FS30i-B iHMI, FS31i-B, FS31i-B5, FS32i-B, FS31i-WB]

+ Manual handle feed multiple 10 million(R600)

[FS0i-F]

+ Set-up guidance function(S771)

Ver 16.01 (2019.5.24)

[PMC]

- PMC simulation function of FS30i-B has been updated to be equivalent to 40A7/03.

Ver 16.02 (2019.5.30)

- CNC System of FS31i-WB was updated to version G4A1/25.0.

Ver 17.00 (2019.10.1)

- FS0i-F Plus iHMI has been added.

CNC System is version D4G3(D6G3) / 06.

- Machine Composition Creation Tool for FS0i-F/FS0i-F Plus has been added.

(Excluding Academic package)

- CNC System has been updated to following series / version.

+ FS30i-B iHMI : G313 / 29

+ FS30i-B : G313 / 29

+ FS31i-B : G413 / 29

+ FS31i-B5 : G433 / 29

+ FS32i-B : G503 / 29

+ FS0i-F : D4G3(D6G3) / 26

+ FS0i-F Plus : D4G3(D6G3) / 06

- iHMI software of FS30i-B iHMI was updated to version 33.0.

- The following options have been added.(Excluding Academic package)

[FS0i-F]

+ TURN MATE i (with touch panel)(S792)

+ TURN MATE i MDI key operation function(S794)

+ TURN MATE i NC program conversion function(S795)

+ TURN MATE i Expansion of Machining Cycle(S796)

[FS0i-F, FS0i-F Plus]

+ MANUAL GUIDE 0i(S772)

[PMC]

- PMC System of FS0i-F and FS0i-F Plus has been updated to 40B4/03.

Ver 17.10 (2019.10.11)

[FS0i-F]

- The machine composition setting data of TURN MATE i has been updated.

[FS0i-F, FS0i-F Plus]

- The machine composition setting data of MANUAL GUIDE 0i has been updated.

Ver 18.00 (2020.1.29)

- CNC System has been updated to following series / version.

+ FS30i-B iHMI : G313 / 32

+ FS30i-B : G313 / 32

+ FS31i-B : G413 / 32

+ FS31i-B5 : G433 / 32

+ FS32i-B : G503 / 32

+ FS0i-F : D4G3(D6G3) / 28

+ FS0i-F Plus : D4G3(D6G3) / 08

- Manual Guide i System was updated to following series / version.

+ FS30i-B : BX72 / 16

+ FS31i-B : BX72 / 16

+ FS31i-B5 : BX72 / 16

+ FS31i-A : BY70 / 72

+ FS0i-F : BX33 / 23

+ FS0i-F Plus : BX33 / 23

+ FS0i-D : BX32 / 38

[FANUC CNC GUIDE](Excluding Academic package)

- FS30i-B 32AX has been added.

CNC System is version G323 / 32.

Machine Composition Creation Tool does not support FS30i-B 32AX.

- FS30i-B 48AX has been added.

CNC System is version G333 / 32.

For FOCAS2 function, please refer to the "Samples\FOCAS2\Readme2.txt".

Machine Composition Creation Tool does not support FS30i-B 48AX.

[FANUC CNC GUIDE Academic package]

- The following options have been added.

[FS0i-F]

+ TURN MATE i (with touch panel)(S792)

+ TURN MATE i MDI key operation function(S794)

+ TURN MATE i NC program conversion function(S795)

+ TURN MATE i Expansion of Machining Cycle(S796)

[FS0i-F, FS0i-F Plus]

+ MANUAL GUIDE 0i(S772)

Ver 19.00 (2020.4.27)

- The following CNC Systems have been added.

+ FS30i-B Plus : G317 / 03

+ FS31i-B Plus : G417 / 03

+ FS31i-B5 Plus : G437 / 03

+ FS32i-B Plus : G507 / 03

For FOCAS2 function, please refer to the "Samples\FOCAS2\Readme2.txt".

Machine Composition Creation Tool does not support.

- CNC System has been updated to following series / version.

+ FS31i-A : G11D / 24

+ FS30i-B iHMI : G313 / 36

+ FS30i-B : G313 / 36

+ FS30i-B 32AX : G323 / 36

+ FS30i-B 48AX : G333 / 36

+ FS31i-B : G413 / 36

+ FS31i-B5 : G433 / 36

+ FS32i-B : G503 / 36

+ FS31i-WB : G4A1 / 27

+ FS0i-F : D4G2(D6G2)/31

+ FS0i-F Plus : D4G3(D6G3)/11

- Manual Guide i System was updated to following series / version.

+ FS30i-B : BX72 / 19

+ FS31i-B : BX72 / 19

+ FS31i-B5 : BX72 / 19

+ FS32i-B : BX72 / 19

+ FS31i-A : BY70 / 73

+ FS0i-F : BX34 / 15

+ FS0i-F Plus : BX34 / 15

+ FS0i-D : BX32 / 39

- Series / version number display of the CNC function was changed thoroughly to

actual CNC.

It influences the following functions.

It is possible to return it to the past display with Setting Management Tool.

+ CNC screen display

+ FOCAS2 (cnc_sysinfo)

+ C language executor function (cnc_sysinfo)

+ FANUC PICTURE (sysinfo)

+ Macro Executor (window function)

+ PMC Ladder (window function)

[PMC]

- PMC System of FS31i-A has been updated to 40A0/32.

- PMC System of FS30i/31i/32i-B has been updated to 40B7/07.

Ver 19.10 (2020.8.20)

- No longer necessary to set the environment variable NSP_HOST.

- CNC System has been updated to following series / version.

+ FS30i-B iHMI : G313 / 40

+ FS30i-B : G313 / 40

+ FS30i-B 32AX : G323 / 40

+ FS30i-B 48AX : G333 / 40

+ FS31i-B : G413 / 40

+ FS31i-B5 : G433 / 40

+ FS32i-B : G503 / 40

+ FS30i-B Plus : G317 / 05

+ FS31i-B Plus : G417 / 05

+ FS31i-B5 Plus : G437 / 05

+ FS32i-B Plus : G507 / 05

+ FS0i-F : D4G2(D6G2)/33

+ FS0i-F Plus iHMI : D4G2(D6G2)/14

+ FS0i-F Plus : D4G3(D6G3)/14

- Manual Guide i System was updated to following series / version.

+ FS30i-B iHMI : BX72 / 21

+ FS30i-B : BX72 / 21

+ FS31i-B : BX72 / 21

+ FS31i-B5 : BX72 / 21

+ FS32i-B : BX72 / 21

+ FS30i-B Plus : BX72 / 21

+ FS31i-B Plus : BX72 / 21

+ FS31i-B5 Plus : BX72 / 21

+ FS32i-B Plus : BX72 / 21

+ FS31i-A : BY70 / 74

+ FS0i-F : BX34 / 17

+ FS0i-F Plus : BX34 / 17

+ FS0i-D : BX32 / 40

- iHMI System has been updated to following series / version.

+ FS30i/31i/32i-B : K777 / 40

+ FS30i/31i/32i-B Plus : K779 / 05

- The following options were able to be used.

[FS30i/31i/32i-B, FS30i-B iHMI FS30i/31i/32i-B Plus, FS35i-B, PMi-A]

+ MIDDLE-LEVEL TASK OF C LANGUAGE EXECUTOR(R550)

[FS30i/31i/32i, FS30i-B 32AX/48AX, FS30i-B iHMI, FS30i/31i/32i-B Plus]

+ NONVOLATILE MEMORY EXPANSION 64K(J993#64K)

+ NONVOLATILE MEMORY EXPANSION 256K(J993#256K)

[FS31i-LB]

+ INTERFERENCE CHECK FOR ROTARY AREA(S643)

[iHMI]

- iHMI software was updated to following series / version.

+ FS30i-B iHMI : K777 / 40

+ FS0i-F Plus iHMI : K779 / 5

- The display of iHMI has been improved.

+ iHMI mode has been added in FS30i-B iHMI and FS0i-F Plus iHMI.

Picture mode and window mode have been removed.

+ The following is supported.

+ Display multiple windows.

+ Display in any position of the windows.

+ Dual display is recommended.

Ver 19.20 (2020.11.18)

- iHMI has been enabled on the following models.

Optional setting of "iHMI basic function(R901)" is required to use iHMI.

+ FS30i/31i/32i-B

+ FS30i-B AX32/AX48

+ FS31i-B5

+ FS30i/31i/32i-B Plus

+ FS31i-B5 Plus

+ FS0i-F Plus

- The following integrated models have been removed.

+ FS30i-B iHMI

+ FS0i-F Plus iHMI

- CNC System has been updated to following series / version.

+ FS30i-B : G313 / 43

+ FS30i-B 32AX : G323 / 43

+ FS30i-B 48AX : G333 / 43

+ FS31i-B : G413 / 43

+ FS31i-B5 : G433 / 43

+ FS32i-B : G503 / 43

+ FS30i-B Plus : G317 / 08

+ FS31i-B Plus : G417 / 08

+ FS31i-B5 Plus : G437 / 08

+ FS32i-B Plus : G507 / 08

+ FS0i-F : D4G2(D6G2)/36

+ FS0i-F Plus : D4G3(D6G3)/17

- TURN MATE i System has been updated to following series / version.

+ FS0i-F : BW02 / 04

+ FS0i-F Plus : BW02 / 04

TURN MATE i Expanded function(S947) is not supported.

- iHMI System has been updated to following series / version.

+ FS30i/31i/32i-B : K777 / 44

+ FS30i/31i/32i-B Plus : K788 / 03

- The following options have been added.

[FS30i/31i/32i-B Plus, FS30i/31i/32i-B, FS30i-B 32AX/48AX, FS0i-F Plus, FS0i-F]

+ High-speed position switch(J987)

[FS30i/31i/32i-B Plus, FS30i/31i/32i-B, FS30i-B 32AX/48AX, FS0i-F Plus]

+ iHMI basic function(R901)

[FS30i/31i/32i-B Plus, FS30i/31i/32i-B, FS0i-F Plus]

+ iHMI set-up guidance(R910)

+ iHMI machining cycle(for 1 path system)(R911)

+ iHMI machining cycle(for 2 path system)(R912)

[FS30i/31i-B Plus, FS30i/31i-B]

+ iHMI machining cycle(for 3 path system)(R913)

+ iHMI machining cycle(for 4 path system)(R914)

[FS30i/31i/32i-B Plus]

+ iHMI kit(R099)

[FS0i-F Plus]

+ TURN MATE i (with touch panel)(S792)

+ TURN MATE i MDI key operation function(S794)

+ TURN MATE i NC program conversion function(S795)

+ TURN MATE i Expansion of Machining Cycle(S796)

- OPERATOR'S MANUAL has been separated into SETUP and OPERATION,

and added specification number to the file name.

[FS31i-LB]

- The function of laser cutting machine has been able to execute commands without

setting the relevant parameters of the laser oscillator connection.

Ver 20.10 (2021.1.18)

- The following CNC Systems have been added.

+ FS30i-B Plus 72AX : G3GD / 03

[FS0i-F Plus, FS30i-B Plus, FS31i-B Plus, FS31i-B5 Plus, FS32i-B Plus]

- The machine composition setting data has supported PMC Message file.

Ver 20.11 (2021.1.28)

- Cycle Time Estimate Function of CNC GUIDE have supported the following CNC Systems.

+ FS30i-B Plus : G317 / 08

+ FS31i-B Plus : G417 / 08

+ FS31i-B5 Plus : G437 / 08

+ FS32i-B Plus : G507 / 08

Ver 20.13 (2021.2.5)

- iHMI System has been updated to following series / version.

+ FS30i/31i/32i-B : K777 / 45

Ver 20.14 (2021.2.18)

- MeasurementAPP of iHMI System has been supported the following series / version.

+ FS30i/31i/32i-B : K777 / 45

Ver 21.00 (2021.4.23)

- The following CNC System has been added.

+ FS35i-B 16AX : G613 / 46

- Machine Composition Creation Tool has supported the following CNC Systems.

+ FS30i-B Plus : G317 / 10

+ FS31i-B Plus : G417 / 10

+ FS31i-B5 Plus : G437 / 10

+ FS32i-B Plus : G507 / 10

+ FS30i-B 32AX : G323 / 46

+ FS30i-B 48AX : G333 / 46

+ FS35i-B 16AX : G613 / 46

- Cycle Time Estimate Function of CNC GUIDE has supported the following CNC Systems.

+ FS0i-F : D4G2/D6G2 / 38

+ FS0i-F Plus : D4G3/D6G3 / 19

+ FS30i-B 32AX : G323 / 46

+ FS30i-B 48AX : G333 / 46

- CNC System has been updated to following series / version.

+ FS31i-A : G11D / 28

+ FS0i-F : D4G2/D6G2 / 38

+ FS0i-F Plus : D4G3/D6G3 / 19

+ FS30i-B : G313 / 46

+ FS30i-B 32AX : G323 / 46

+ FS30i-B 48AX : G333 / 46

+ FS31i-B : G413 / 46

+ FS31i-B5 : G433 / 46

+ FS32i-B : G503 / 46

+ FS30i-B Plus : G317 / 10

+ FS31i-B Plus : G417 / 10

+ FS31i-B5 Plus : G437 / 10

+ FS32i-B Plus : G507 / 10

- Manual Guide i System has been updated to following series / version.

+ FS31i-A : BY70 / 76

+ FS31i-D : BX32 / 42

+ FS0i-F : BX34 / 21

+ FS0i-F Plus : BX34 / 21

+ FS30i-B : BX72 / 26

+ FS31i-B : BX72 / 26

+ FS31i-B5 : BX72 / 26

+ FS32i-B : BX72 / 26

+ FS30i-B Plus : BX72 / 26

+ FS31i-B Plus : BX72 / 26

+ FS31i-B5 Plus : BX72 / 26

+ FS32i-B Plus : BX72 / 26

- FANUC PICTURE application transferring function for CNC GUIDE from FP editor has been supported.

- The following options have been added.

[FS30i/31i/32i-B, FS30i-B 32AX/48AX, FS30i/31i/32i-B Plus]

+ DUAL CHECK SAFETY(S661)

[FS0i-F]

+ SPINDLE ORIENTATION(J853)

[FS0i-F, FS0i-F Plus, FS30i/31i/32i-B, FS30i-B 32AX/48AX, FS30i/31i/32i-B Plus]

+ HIGH-SPEED SKIP(J848)

[FS35i-B]

+ HIGH-SPEED POSITION SWITCH(R704)

[FS31i-A]

+ HIGH-SPEED POSITION SWITCH(J987)

[FS0i-F, FS0i-F Plus, FS31i-A, FS30i/31i/32i-B, FS30i-B 32AX/48AX, FS30i/31i/32i-B Plus]

+ PMC AXIS CONTROL ACCELERATION/DECELERATION SPECIFICATION FEED(R640)

[FS0i-F, FS35i-B]

+ INTERRUPTION TYPE CUSTOM MACRO(J874)

[FS0i-F, FS0i-F Plus]

+ TURN MATE i Expanded function(S947)

- The following improvements have been applied:

[PMi-A]

+ Virtual MDI key

[PMC]

- PMC System of FS30i/31i/32i-B has been updated to 40B7/09.

- DCSPMC function has been supported. (Machine signal simulator is not available for DCSPMC.)

Ver 21.10 (2021.06.11)

- The following problem is corrected.

+ When files in memorycard are displayed at PMC data I/O screen,

wrong file information is displayed. (FS0i-F, FS0i-F Plus)

Ver 21.20 (2021.06.30)

- iHMI System has been updated to following series / version.

+ FS30i/31i/32i-B : K777 / 50

+ FS30i/31i/32i-B Plus : K788 / 08

+ FS0i-F Plus : K779 / 11

- The following options have been added.

[FS30i/31i/32i-B, FS30i-B 32AX/48AX]

+ RIGID TAP(J828)

[FS0i-F, FS0i-F Plus, FS30i/31i/32i-B, FS30i-B 32AX/48AX]

[FS30i/31i/32i-B Plus, FS30i-B Plus 72AX]

+ CUSTOM SOFTWARE SIZE 16MB(J738#16M)

[FS0i-F, FS0i-F Plus, FS30i/31i/32i-B, FS30i-B 32AX/48AX]

[FS30i/31i/32i-B Plus, FS30i-B Plus 72AX, FS35i-B 16AX]

+ CUSTOM SOFTWARE SIZE 12MB(J738#12M)

[PMC]

- Machine signal simulator has become available for DCSPMC.

Ver 22.00 (2021.8.4)

- The following CNC System has been added.

+ FS35i-B Line : G641 / 27

- The following improvements have been applied:

[FS32i-B Line]

+ Start from machine composition setting data has become available.

[FS30i/31i/32i-B Plus, FS30i-B Plus 72AX]

+ In the machine composition setting data,

parameters that option can be set enable or disable set '0'.

[FS30i-B, FS30i-B Plus]

+ In the case of the machine composition setting data that uses iHMI,

the following option set enable by default.

iHMI MACHINING CYCLE(FOR 1 PATH SYSTEM)(R911)

iHMI MACHINING CYCLE(FOR 2 PATH SYSTEM)(R912)

iHMI MACHINING CYCLE(FOR 3 PATH SYSTEM)(R913)

iHMI MACHINING CYCLE(FOR 4 PATH SYSTEM)(R914)

[FS0i-F, FS0i-F Plus]

+ The following options were able to be used with MANUAL GUIDE i enabled.

Loader control function(R417)

Addition of loader control path(R418)

Ver 22.20 (2021.10.5)

- The following problem is corrected.

+ When Information Center of iHMI is displayed,

the contents of Display Details may not correct. (FS30i/31i/32i-B Plus)

+ The comments of parameter screen may not correct. (FS35i-B Line)

+ In iHMI, 4-digit G-code cycle may not be executed. (FS30i/31i/32i-B, FS30i/31i/32i-B Plus, FS0i-F Plus)

+ In machining simulation of MANUAL GUIDE i, tool rotary axis

during the polar coordinate interpolation with inch input is not drawn correctly.

(FS30i-A, FS0i-D, FS30i/31i/32i-B, FS30i/31i/32i-B Plus, FS0i-F, FS0i-F Plus)

Ver 24.10 (2022.2.10)

NOTICE: About update of FS32i-B Line from Ver. 24.0 or earlier to Ver. 24.1,

Please refer to "5 UPDATE OF CNC GUIDE" of "A-42148-00360EN_CNC GUIDE Function for transfer line.pdf".

- MOP Simulator has been supported.

- Cycle Time Estimate Function of CNC GUIDE have been supported

that estimate the first path of multi path systems.

- The following CNC System has been added.

+ FS32i-B Plus Line : G547 / 18

- iHMI System has been supported to following series / version.

+ FS32i-B Plus Line : K785 / 03

- CNC System has been updated to following series / version.

+ FS0i-F : D4G2/D6G2 / 47

+ FS0i-F Plus : D4G3/D6G3 / 28

+ FS30i-B : G313 / 54

+ FS30i-B 32AX : G323 / 54

+ FS30i-B 48AX : G333 / 54

+ FS31i-B : G413 / 54

+ FS31i-B5 : G433 / 54

+ FS32i-B : G503 / 54

+ FS35i-B 16AX : G613 / 54

+ FS30i-B Plus : G317 / 18

+ FS31i-B Plus : G417 / 18

+ FS31i-B5 Plus : G437 / 18

+ FS32i-B Plus : G507 / 18

+ FS30i-B Plus 72AX : G3GD / 11

+ FS32i-B Line : G541 / 27

- iHMI System has been updated to following series / version.

+ FS0i-F Plus : K779 / 12

- The following options have been added.

[FS30i/31i/32i-B, FS30i-B 32AX/48AX, FS35i-B 16AX, FS30i/31i/32i-B Plus,

FS30i-B Plus 72AX, FS0i-F, FS0i-F Plus]

+ Safety function by FL-net(S851)

+ Ethernet/IP Adapter Safety function(R976)

+ PMC allocation expansion of PROFINET IO Controller function(R979)

+ Ethernet/IP Scanner PORT2 function(R973)

+ Ethernet/IP Adapter PORT2 function(R974)

+ PROFINET IO Controller function(R971)

+ PROFINET IO Device function(R972)

+ Ethernet/IP Scanner function(R966)

+ Ethenret/IP Adapter function(R967)

+ PROFINET IO Device Safety function(R977)

+ FL-net PORT2 function(R964)

+ Modbus/TCP Server function(R968)

+ Ethernet function(S707)

+ FL-net function(J692)

The above functions support the screen only.

[PMi-A]

+ HIGH-SPEED POSITION SWITCH(R704)

[FS32i/35i-B Line]

+ Spindle Orientation (J853)

+ Spindle Output Switching Function (J854)

+ Extended Spindle Orientation (J861)

+ Extended Spindle Output Switching Function (J862)

The above functions support the signal only.

- The following improvements have been applied:

[FS0i-F Plus]

+ Standard MDI unit (QWERTY keys) has become available.

(Only Window Mode)

[FS0i-F, FS0i-F Plus]

+ The macro of Set-up guidance function has become available.

Ver 24.20 (2022.4.8)

- The following CNC System has been added.

+ FS30i-LB Plus : G3D7 / 5

Ver 24.30 (2022.5.20)

- The following problem is corrected.

+ Some Reading Diagnosis Data (High-speed Response) functions that terminates abnormally with PMC Window are changed to return completion code 3. (The specified diagnosis data number is invalid)

Ver 24.40 (2022.5.27)

- The following problem is corrected.

+ If CNC GUIDE is forcibly terminated while rewriting the parameter, the parameter may become incorrect after the next launch.

Ver 25.00 (2022.5.31)

- The following CNC System has been added.

+ FS0i-LF Plus : DCG3 / 09

+ FS30i-LB : G3D5 / 21

- iHMI System has been supported to following series / version.

+ FS0i-LF Plus : K787 / 14

+ FS30i-LB Plus : K789 / 09

+ FS30i-LB : K778 / 16

- CNC System has been updated to following series / version.

+ FS0i-F : D4G2/D6G2 / 49

+ FS0i-F Plus : D4G3/D6G3 / 30

+ FS30i-B : G313 / 55

+ FS30i-B 32AX : G323 / 55

+ FS30i-B 48AX : G333 / 55

+ FS31i-B : G413 / 55

+ FS31i-B5 : G433 / 55

+ FS32i-B : G503 / 55

+ FS35i-B 16AX : G613 / 55

+ FS30i-B Plus : G317 / 19

+ FS31i-B Plus : G417 / 19

+ FS31i-B5 Plus : G437 / 19

+ FS32i-B Plus : G507 / 19

+ FS32i-B Plus Line : G547 / 19

+ FS30i-B Plus 72AX : G3GD / 12

- iHMI System has been updated to following series / version.

+ FS0i-F Plus : K797 / 03

+ FS30i/31i/32i-B : K795 / 06

+ FS30i/31i/32i-B Plus : K796 / 08

- The following options have been added.

[FS30i/31i/32i-B, FS30i-B 32AX/48AX, FS30i/31i/32i-B Plus,

FS30i-B Plus 72AX, FS0i-TF, FS0i-TF Plus]

+ 4th/5th axis offset(R517)

[FS30i/31i/32i-B Plus, FS30i-B Plus 72AX]

+ Tool posture turning(R338)

+ Speed control with acceleration in circular interpolation(J809)

+ Optimum torque acceleration/deceleration(S675)

[FS30i/31i/32i-B Plus]

+ High-speed processing(S809)

- The following improvements have been applied:

[FS0i-F Plus]

+ CNC Screen size 15/19 inch has become available.

(19 inch display is only Window Mode)

- The following problem is corrected.

+ If Italian, Russian, Bulgarian, or Hindi is selected as the input language for Windows, warning dialog will be displayed when CNC GUIDE is launched.

[FS0i-D]

+ If you restart immediately after creating new program on the O list screen of MANUAL GUIDE i, and press new soft key on the O list screen, the screen will be frozen.

** Microsoft, Windows, and .NET Framework are registered trademarks of

Microsoft Corporation in the United States.

** Pentium and Core are registered trademarks of Intel Corporation.