很古老的软件了,适用于老设备维护,支持Windows 95, NT 4.0 ,XP操作系统,其他操作系统兼容性未知.此应用程序是用于单轴到四轴机器人控制器的机器人控制器和机器人支持软件。

安装文件下载:

百度网盘下载链接.txt

(754 Bytes, 售价: 50 E币)

百度网盘下载链接.txt

(754 Bytes, 售价: 50 E币)

注意:请确保您所用的网络可以访问百度网盘并能熟练使用百度网盘下载文件,若附件内下载链接失效不能下载,可以回复本文留下邮箱给您发送可用链接。

此应用程序可以通过以下方式使用:

在计算机上创建和编辑程序、点或参数数据作为与机器人控制器一起使用的文件。(离线编辑)。

操作或观察连接到机器人控制器的机器人的状态。

创建和编辑与机器人控制器一起使用的程序、点或参数数据目录。 (在线编辑)

将创建或编辑的程序、点或参数数据从计算机上传到机器人控制器。

将机器人控制器程序、点或参数数据下载到计算机。

Single Axis:SRC, SRCA, ERC, SRCH, SRCH-E, ERCX, SRCX, SRCP, SRCD, ERCDSR1-X, SR1-P

Double Axes:DRC, DRCA, DRC-R, DRCH, DRCH-E, DRCX

Double to Quadruple Axes:TRCH, TRCX

[1] Precautions

[2] About POPCOM Windows

[3] Package contents

[4] Required system environment

[5] Install and Un-install

[6] Directory structure

[7] Start and Exit

Microsoft, Windows and Windows NT are trademarks of Microsoft Corporation.All other company and product names mentioned are trademarks or registered trademarks of their respective owners.

[1] Precautions

(*) As a rule, separate software sets should be purchased for each computer.

(*) This software, help and manual may not be used or reproduced in part or in their entirety without permission.

(*) Responsibility is not accepted for any situations that may occur as a result of using this software, help or manual.

(*) The specifications of this software, and information contained in manual and help, may be updated without notice.

(*) The contents of this product are considered to be fully adequate and satisfactory. Should the user have any questions or concerns, however, about this software or information contained in help and manual, please contact your agent.

(*) Prepare to enter emergency stop input for safe when moves any axis by using automatic operation, step operation, manual movement and

trace operation.

[2] About POPCOM Windows

This application is assistant software for single to quadruple axes robot controller and robots. This application can be used in the following ways:

(*) Backup current data from robot controller.

(*) Restore previously saved data to robot controller.

(*) Operate robot controller and robots directly.

(*) Modify robot controller data directly.

(*) Modify various data as file on your computer.

[3] Package contents

[Setup disk]

CD-ROM

[Serial communication cable (Option)]

9 pins - 25 pins (for IBM-PC/AT or compatibles)

P/N: KR7-M538F-100 (for POPCOM/VIP/CUP)

P/N: KD4-M538F-010 (for POPCOM)

Memo

1. There is an emergency stop signal input between pin nos. 18 and 21 on the robot controller side. Under normal circumstances this contact is closed (it is a B-type contact). When you want to be able to use an emergency stop signal, connect a switch retard for 50 mA or greater. If this circuit is open, an emergency stop is performed.Input response: 5 msec or lessInput current: 33.3 mA/DC 24V

2. ERCD robot controller needs special 9 pins (Plug) - 25 pins (Socket) straight serial conversion adapter (P/N: KAX-M657E-000) to communicate with your computer.

[4] Required system environment

[Personal computer]

PC with an 80386-processor minimum

32MB of RAM minimum

2MB of available hard-disk space minimum

CD-ROM drive x4 speed or more

Serial communication port

(*) USB-Serial adapter that can through any control code and

manage XON/XOFF flow control can be used.

[Operation Software]

Microsoft Windows 95, NT 4.0 or later operating system

[Robot controller and robot]

Single Axis:SRC,SRCA,SRCH,SRCH-E,ERC,SRCX,SRCP,SRCD,ERCD,SR1-X,SR1-P

Double Axes:DRC,DRCA,DRC-R,DRCH,DRCH-E,DRCX

Double to Quadruple Axes:TRCH,TRCX

(*) To operate robot from your computer, it is necessary to connect robots to robot controller and complete to setup robot controller for the robots.

[5] Install and Un-install

Installing to hard disk on your computer is necessary for operating POPCOM Windows. If previous version of POPCOM Windows was installed on

your computer, please remove it before installing.

[Install]

1. Insert disk into the CD-ROM drive. The setup program should start automatically. If the setup program does not start, double-click install.exe from the directory window for your CD-ROM drive.

2. Follow the instructions on your screen.

[Un-install]1. Click [Uninstall] item in [POPCOM Windows] under [Programs] on [Start] menu.2. Follow the instructions on your screen.3. Delete configuration settings file POPCOM.INI file in the

Windows folder using Windows Explorer.

[Un-install by manual]

1. Delete folder (POPCOM) where POPCOM Windows was installed by using Windows Explorer.

2. Delete configuration settings file POPCOM.INI file in the Windows folder by using Windows Explorer.

3. Click [Taskbar and Start Menu] under [Settings] on [Start] menu.

4. Click [Advanced] tab in [Taskbar and Start Menu Properties] dialog box, then click [Advanced...] button in [Start menu] group.

5. Expand [Programs] and delete [POPCOM Windows] folder.

[6] Directory structure

When setup was completed, files are installed in the specified directory (folder).

POPCOM.EXE

POPLANG.DLL

POPCOM.HLP

README.TXT

UPDATE.TXT

[7] Start and Exit

[Start]

1. Click [POPCOM] item in [POPCOM Windows] under [Programs] on [Start] menu.

2. [Select] dialog box of POPCOM Windows is shown.

3. Click [Cancel] button to open an empty [Main] window. (*) If POPCOM needs too many time to startup, please check "Run in separate memory space" in advanced properties of the shortcut for Windows 2000/XP.

[Exit]

1. Click [Exit] command in [File] menu to quit the application. Or, double click system menu box in [Main] window.

2. When unsaved data exists in [File Editor] window, a message box that suggest saving data to file is shown.

3. When [Robot Operate] window is opened with automatic operation, a message box that suggest to stop running is shown.

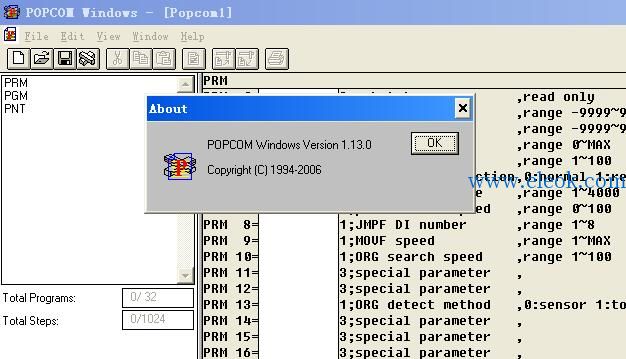

[Updates in version 1.13.0]

1. Corresponding to SR1-X/SR1-P robot controller.

2. Correct default DPBVER from 260 to 300.

3. Corresponding to IN/OUT/LET command for ERCX/SRCX/DRCX,SRCP/SRCD robot controller.

4. Add version string in first line of file which already contains type of robot controller.

5. Fix the bug that load to DRC/DRCA/DRC-R operation was failed and open operation was recognized as DRCX if PRM19 contains version in

specified file for DRC series robot controller.

6. Fix the bug that minor version was beginning from 50 for DRC-R robot controller.

7. Fix the bug that abnormal message box was shown in [DIO] dialog box when external I/O was operated.

8. Prohibit to connect with DC/AC type robot controller by using CE typed DPBVER.

9. Update parameter comment message in [File Edit] window and [Online Edit] dialog box.

10. Improve to use "@READ ALL" command while saving except DC series and 49 or less minor version of robot controller.

11. Improve to show version and numbers of axis in [File Option] dialog box.

12. Deregulate to exchange program and point while upload and download operation.

13. Handle file extension as "data type" and prohibit sending data that excluded in "data type" at system-load operation.

Ex: Prohibit loading PNT and PRM data in PGM file extension.

Prohibit loading PGM and PRM data in PNT file extension.

Prohibit loading PGM and PNT data in PRM file extension.

14. Remove unused unit selection in [CC-Link Settings] and [DeviceNet Settings] dialog box.

15. Permit to change node and speed in [DeviceNet Settings] dialog box while SR1 robot controller and set system = 1:S/W.

16. Fix the bug that key scrolling operation is prohibited in list box of [Alarm History] and [Error History] dialog box.

17. Fix the bug that "305:Invalid Option 1" is shown when option 2 of LET command contains error.

18. Fix the bug that [Save] icon on the toolbar is enabled while operating [Output] window.

19. Change default install folder to "C:\Program Files\POPCOM".

[Updates in version 1.12.0]

1. Corresponding to ERCD robot controller.

2. Append realtime update function in DIO dialog box.

3. Append warning message "CAUTION: BUSY signal may turns off while robot controller is running." in [DIO] dialog box.

4. Append warning message "CAUTION: BUSY signal turns off while robot controller is running." in [Watch] dialog box.

5. Fix the bug that Task0 specified in TON and TOFF command occurs no error message when data checked.

[Updates in version 1.11.1]

1. Corresponding to palette command for single axis robot controller.

2. Improve to check version strictly before loading parameter between file and robot controller in system - load operation if file contains version parameter.

3. Improve to check version strictly before uploading/downloading between window and robot controller in upload/download operation.

4. Improve to show robot controller type strictly in open operation if file contains version parameter.

5. Fix the bug that useless command were shown in function bar.

[Updates in version 1.11.0]

1. Corresponding to Profibus option.

2. Append warning message "some of parameter need to reboot to take effect" in system - load operation.

3. Append warning message "SRCP turn servo off by this operation" in generation dialog box.

4. Fix the bug that [OK] message was shown prior to complete writing file in system - save operation.

5. Fix the bug that [Set Robot Layout] dialog box was unexpectedly closed when [Update] button was clicked.

6. Fix the bug that [Set Standard Coordinate] dialog box was unexpectedly closed when [Update] button was clicked.

7. Fix the bug that changing arm length was rarely ignored in [Set Standard Coordinate] dialog box.

[Updates in version 1.10.0]

1. Corresponding to SRCP/SRCD robot controller.

2. Corresponding to error history function for X series (V*.50 and after), SRCP and SRCD robot controller.

3. Corresponding to matrix function for SRCX, SRCP and SRCD robot controller.

4. Improve parameter comment message.

5. Improve that robot type (0, 18/72/112/152/192) cannot be edit while parameter online editing.

6. Improve that entire parameter are reloaded automatically when weight (3, 50/90/130/170) was modified.

7. Improve that entire parameter are reloaded automatically when lead (12, 60/100/140/180) was modified.

8. Improve that warning message to be rebooting is shown when option type was modified.

9. Fix the bug that no error message was shown while saving file into disk drive which has not enough disk space.

[Updates in version 1.9.5]

1. Permit using point and parameter comment.

2. Change to delay sequence while transmitting program name from before to after.

3. Improve operation to switch enable/disable service mode and option type in [System] dialog box.

4. Add history function for H and X series robot controller in [System] dialog box. Save error log to file is also prepared.

5. Minimize displaying error when no program registered in robot controller.

6. Fix the bug that data error sometimes occurs when option type was checked.

[Updates in version 1.9.4]

1. Fix the bug that failed to use file contains in the folder named in multiple-byte characters.

2. Fix the bug that connecting to robot function failed, recognize as an alarm, when receive buffer size < 64 byte.

3. Add French version. (resource string only)

4. Fix the bug that XON/XOFF flow control does not work well.

5. Fix the bug that data error occurs during reading file on Windows 2000.

[Updates in version 1.9.3]

1. Corresponding to new function for ethernet option.

2. Corresponding to new X-series robot which needs to expand some parameters.

3. Append 80 characters limit while editing in [Online Edit] dialog box.

4. Improve parameter printing which include comments.

5. Improve parameter display in [Online Edit] dialog box to show entire comments in the list box.

6. Improve output display to show number as line when data checked.

7. Improve error display to show complete line when data checked before uploading.

8. Fix the bug that printing font is much bigger than specified size.

9. Increase maximum parameter number from 61 to 63.

[Updates in version 1.9.2]

1. Fix the bug that incorrect PRM33 comment was shown for single axis robot controller.

2. Fix the bug that point number was limited to 254 in [Point Trace] dialog box for X series robot controller.

3. Fix the bug that [About] dialog box shows version 1.9.

[Updates in version 1.9.1]

1. Corresponding to CC-Link/DeviceNet/Ethernet option.

2. Corresponding to Service Mode.

3. Fix the bug that ORGN/SRVO/DRVA/DRVI commands with option cause data error when executing data check.

[Updates in version 1.9]

1. Corresponding to TRCX2 robot controller.

2. Add serial port COM5 and COM6 selection.

3. Correct default DPBVER from 251 to 212.

4. Add reload function in [Online Edit] dialog box.

5. Update function bar command list for the window setting which can be pasted to.

6. Update parameter comment list and data check range when minor version in the option dialog box was changed.

7. Fix the bug that incorrect origin search method was shown in the [Origin] dialog box.

8. Fix the bug that incorrect PRM48 and 49 comment were shown for ERCX/SRCX.

9. Fix the bug that undoing causes application error while area is selected.

10. Parameter comment files (*.CUP) are included in the application.

11. Corresponding to USB-Serial converter GoHubs,Inc GO-COM232(TM).

12. Limit mouse left button within editing area.

13. Set default extension when no extension specified.

14. Fix the bug that origin status was not updated after mark origin was completed.

15. Fix the bug that origin status was not updated after changing origin search method.

16. Correct balloon message for M142,143,146,147 in [DIO] dialog box.

17. Fix the bug that incorrect error message was shown while checking point data.

18. Unify [Robot Layout] dialog box to parameter initialization.

19. Do not ignore changing generation when same value was set.

20. Fix the bug that current status in [Utility] dialog box was not updated when an error occurs by operating button.

[Updates in version 1.8]

1. Corresponding to ERCX/SRCX/DRCX/TRCX robot controller.

2. Fix the bug that memory leak occurs when replace dialog operation failed.

[Updates in version 1.7]

1. Fix the bug that General Protection Error or Exception occurs while editing file.

2. Fix the bug that list box cannot select items when no program data exist in the robot controller while selecting downloading data.

3. Fix the bug to paste multiple lines in the PNT/PRM pane window.

4. Correct order to initialize data in the robot controller.

5. Improve cursor position when releasing the selected field.

6. Improve selected field display in the PNT/PRM pane window.

7. Improve user I/F to enter DPBVER when connecting the robot controller.

8. Append DPBVER empty check.

9. Append warning when DPBVER was set with 'E' but actual robot controller do not CE type.

10. Improve robot controller name for the CE type robot controller.

11. Improve user I/F in the [System] dialog box to select load option.

12. Improve user I/F in the [Robot Option] dialog box to show editable or not.

13. Corresponding to save ALL data for the old type SRC/DRC robot controller.

[Updates in version 1.6]

1. Change install program to InstallShied(TM).

2. Corresponding to TRCH robot controller.

3. Unite program, point, parameter edit window to file edit window.

4. Add page layout function in the [File] menu.

5. Abandon function to convert point data units.

6. Improve user I/F while uploading and downloading.

7. Add font function in the [View] menu.

[Updates in version 1.5]

1. Fix the bug when STOP command exists in the program on the robot

controller fails receiving program data at System - Save, Download, Show Exe. Program and Program Online Edit.

[Updates in version 1.4]

1. Fix the bug when transmitting 16 byte or more data occurs timeout or hung up.

2. Abandon function to cancel communication by [ESC] key.

3. Fix the bug to initialize transmitting time out.

4. Fix the bug to connect DRC(DC) with old type ROM version.

5. Improve spin button direction.

6. Fix the bug to save point or position trace speed value.

7. Improve BUSY signal in the DIO dialog box.

8. Improve user I/F while connecting robot controller and clear alarm.

9. Fix the bug MIO signals can operate on DRC(DC)/DRCA.

10. Improve function bar to show always in the right side of program edit window.

11. Abandon function to close dialog box when clicked outside of dialog box.

12. Improve program online edit dialog to create new program and edit program step directly.

13. Improve user I/F for watch, point online edit, palette online edit and parameter online edit dialog box.

14. Append parameter load option in the property dialog box on the robot control window.

15. Append parameter upload option in the property dialog box on the parameter edit window.

16. Append program print option in the property dialog box on the program edit window.

【必读】版权免责声明

1、本主题所有言论和内容纯属会员个人意见,与本论坛立场无关。2、本站对所发内容真实性、客观性、可用性不做任何保证也不负任何责任,网友之间仅出于学习目的进行交流。3、对提供的数字内容不拥有任何权利,其版权归原著者拥有。请勿将该数字内容进行商业交易、转载等行为,该内容只为学习所提供,使用后发生的一切问题与本站无关。 4、本网站不保证本站提供的下载资源的准确性、安全性和完整性;同时本网站也不承担用户因使用这些下载资源对自己和他人造成任何形式的损失或伤害。 5、本网站所有软件和资料均为网友推荐收集整理而来,仅供学习用途使用,请务必下载后两小时内删除,禁止商用。6、如有侵犯你版权的,请及时联系我们(电子邮箱1370723259@qq.com)指出,本站将立即改正。

|

|